Tailings Management

Surface tailings impoundments can represent some of the most significant safety and environmental risks for the mining industry. Lundin Mining takes considerable care to ensure our tailings facilities are well-designed, built in accordance with leading industry practices and standards, well operated and maintained, inspected, independently reviewed, and carefully monitored.

Policies and Standards

Lundin Mining’s Responsible Mining Policy and Responsible Mining Management Systems (RMMS) include tailings specific principles and standards. All Lundin Mining’s operations manage their tailings in accordance with the Tailings Management Standard, developed in 2015, and recently updated to align to the Global Industry Standard on Tailings Management (GISTM). The updated Tailings Management Standard requires that for all tailings facilities throughout the entire lifecycle, from planning and design, construction, operation, closure, and post-closure, implementation of leading practices will be carried out to ensure:

- Zero harm to people and the environment;

- All aspects comply with Lundin Mining policies and standards and accepted international practice;

- All aspects comply with the commitments to stakeholders; and

- Leadership, personal commitment, and accountability from all employees, consultants, and contractors is embedded throughout all aspects of tailings management.

Monitoring and Surveillance

A requirement of the Tailings Management Technical Standard is for all sites to conduct regular geotechnical, hydrogeological and environmental monitoring to meet regulatory requirements and prevent the uncontrolled release of tailings and/or water to the environment.

All operations employ monitoring and surveillance systems which may include surface prisms, piezometers, inclinometers, remote sensing and other technologies to monitor tailings dams and water levels. Trigger action response plans (TARPs) provide clear guidance on how to respond to pre-determined trigger levels for surveillance activities.

All active tailings facilities have a closure plan which includes long-term monitoring requirements. The monitoring plan for the closed Ojos del Salado tailings facilities was reviewed in 2021 and additional dam safety instrumentation was installed. Plans to expand monitoring activites will be completed in 2022.

Responsible Person

All operations are required to identify a responsible person to ensure ownership and proper management of the tailings facility. The responsible person ensures procedures for each facility, including an Operating, Maintenance, and Surveillance (OMS) Manual and Emergency Preparedness and Response Plan, are regularly documented, and made available to operations personnel. The responsible person is an appropriately qualified, experienced and site-dedicated individual employed directly by the operation.

Staff Inspections

Tailings dams are regularly inspected by trained operators and technical staff, sometimes as frequently as several times daily, with formal documented staff inspections at least quarterly.

Engineer of Record

Each tailings facility has an appropriately qualified, licensed and experienced third-party geotechnical engineer to act as an Engineer of Record in the relative jurisdiction.

Dam Safety Inspections

Formal dam safety inspections are conducted at least annually by the Engineer of Record, and reports are issued to the responsible person for action on recommendations.

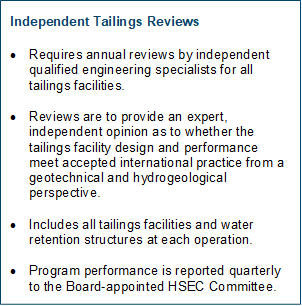

Independent Reviews

A component of the Tailings Management Standard is the requirement for regular independent third-party tailings reviews, which are recognized as a leading practice for effective tailings and water dam stewardship.

Annual site visits for the independent tailings reviews were completed at all operations last year except for Chapada which is planned in early 2022. In addition, online progress meetings with the independent reviewers and Engineer of Record were completed throughout the year to closely track progress made on outstanding recommendations.